BT Transition Couplers

BT Transition Couplers

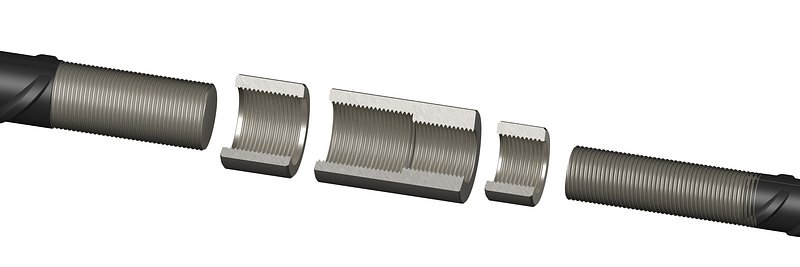

BT Transition couplers are designed to connect reinforcing bars of different diameters whilst still maintaining the full tensile strength of both reinforcing bars, ensuring the failure mode is ductile failure of the smaller bar.

For Type A transition connections, both bars utilise standard Type A BT threads with a special coupler to connect the two bars. Transition connections requiring types B or C systems use the standard BT thread for the smaller bar and a modified BT thread for the larger bar which uses a thread pitch matching the smaller thread to allow simultaneous rotation of the coupler on both bars.

Locknuts for Type C connections use the standard locknut for the smaller bar and a modified locknut with the modified thread pitch for the larger bar.

Download the technical brochure for full product details:

Reinforcing Bar Couplers (PDF, 6.72 MB)

BT Transition Type A

Type A transition connections utilise the same Type A BT threads as the standard system with a special internally threaded coupler to connect the two different sized cold-forged and threaded bar ends together. Type A connections are used where the continuation bar can be rotated

BT Transition Type B

Type B connections utilises a longer thread on the smaller bar equal to the length of the coupler. The thread on the larger bar and the coupler is modified with a pitch matching the smaller thread. The coupler needs to be rotated from the smaller diameter rebar onto the larger. Type B connections are used where the continuation bar can be rotated for no more than one revolution.

BT Transition Type C

The Type C connection utilises the same coupler and thread pitches as for the Type B, together with two locknuts and longer threads on the bar ends. The coupler needs to be rotated from the smaller diameter rebar onto the larger. Type C connections are used where the continuation bar cannot be rotated.

Latest News

Holiday Closing 2026

Our offices will close from Thursday, 25th December 2025 and re-open at our usual business hours on Monday, 5th January 2026.

New Halfen Powerclick 100

The Halfen Powerclick System is a proven innovative technology for pipe supports in large-scale industrial plant construction. We are delighted to announce the addition of Halfen Powerclick 100 to our range, which provides superior on-site solutions for heavy-duty applications that are even more secure and sustainable for customers.