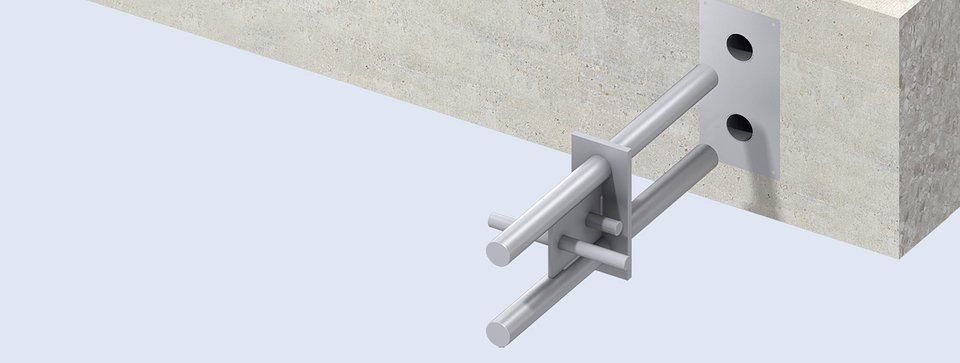

DSD/DSDQ Shear Load Connectors

DSD/DSDQ Shear Load Connectors

Although installation is shown for the Ancon DSD, the procedure is the same for all standard two-part Ancon shear connectors.

The two part design of all Ancon shear connectors removes the need for drilling formwork on site, supporting dowel bars and fitting debonding sleeves and end caps. The installation is a fast and accurate process as demonstrated in the video below.

Nail the sleeve component to the shuttering ensuring that the sleeve is correctly orientated for the direction of the load. Check minimum spacings and edge distances are not exceeded. The label prevents debris from entering into the sleeve and should not be removed at this stage.

Fix the local reinforcement ensuring that the correct cover to the reinforcement is maintained. Pour the concrete to complete the installation of the sleeve component.

When the concrete has achieved sufficient strength, strike the shuttering. Peel off or puncture the label to reveal the holes for the dowels. Where 'Q' versions are being used, the label should only be punctured enough to allow the dowels into the cylindrical sleeve to prevent debris entering the box section.

Position compressible joint filler of the appropriate width, for applications where movement is expected between the two sections of concrete.

Push the dowel component through the joint filler until it is fully located in the sleeve component. It may be necessary to tap the dowel component to overcome the dimple that pinch holds the dowel in the sleeve and prevents dislocation when the concrete is vibrated.

Fix the local reinforcement in position around the dowel component together with any other reinforcement that is required, ensuring that the correct cover to the reinforcement is maintained. Pour the concrete to complete the installation of the shear connector.

Notes

Although installation is shown for the Ancon DSD, the procedure is the same for all Ancon shear connectors.

Where deep concrete pours are proposed, the installation will require further consideration. More robust fixing of the sleeve and dowel components will be necessary, to avoid displacement during placing of the concrete.

Latest News

Holiday Closing 2026

Our offices will close from Thursday, 25th December 2025 and re-open at our usual business hours on Monday, 5th January 2026.

New Halfen Powerclick 100

The Halfen Powerclick System is a proven innovative technology for pipe supports in large-scale industrial plant construction. We are delighted to announce the addition of Halfen Powerclick 100 to our range, which provides superior on-site solutions for heavy-duty applications that are even more secure and sustainable for customers.