Rail Operations Centre, Alexandria, Sydney

Ancon worked closely with the project design team and specialist masonry contractor, Favetti, on the delivery of the new Rail Operations Centre in Alexandria, Sydney. The scale and complexity of this stunning project presented a number of unique challenges, demanding Ancon’s expertise and innovative thinking.

The finished facade at the Rail Operations Centre

A key feature of this striking new building is brick-clad arches spanning the full length of two elevations. With the design requiring bricks on both the soffit and the face of these gigantic arches, it was identified that traditional masonry hanging systems, typically used over shorter brick runs, were not going to be practical here and a different solution was needed.

It was agreed that the bricks would be cast into the structural concrete beams on site.

Bricks with Helifix pin anchors laid in the formwork

The brickwork was positioned within the formwork of the huge concrete beams and Helifix stainless steel helical pins were used to mechanically bond the masonry and concrete together. Helifix, a division of Ancon Building Products, invented the one-piece stainless steel helical tie over thirty years ago. Together with their associated concealed, non-disruptive, installation techniques, Helifix products provide many benefits, from the simplicity of their design to their ease of installation and long-term performance. They combine the required strength with flexibility, durability and great holding power in all commonly-used building materials to produce secure and lasting connections.

One end of the pin was driven into the bricks with the other end left exposed in the beam’s reinforcement cage to form the bond with the concrete when cast.

After curing, the formwork was stripped to reveal the brick facing and the joints were pointed with mortar to look like traditionally laid brickwork.

This system proved to be so successful it was also adopted for the soffits on the deep reveal openings further up the elevation.

Another challenge on the project was the coordination of the complex secondary steelwork frame with Ancon’s masonry support system. These systems were designed for the building’s special features, such as sloping window reveals and splayed feature joints.

To overcome the issues, Ancon used Tekla BIM software to model its support angles around the 3D model provided by the structural steelwork contractor. This collaborative tool enabled support angles to be designed accurately, and all parties were able to visualise the complex arrangements ahead of fabrication and assembly on site.

BIM software used to model Ancon brick support angles

Related Products

Masonry Support

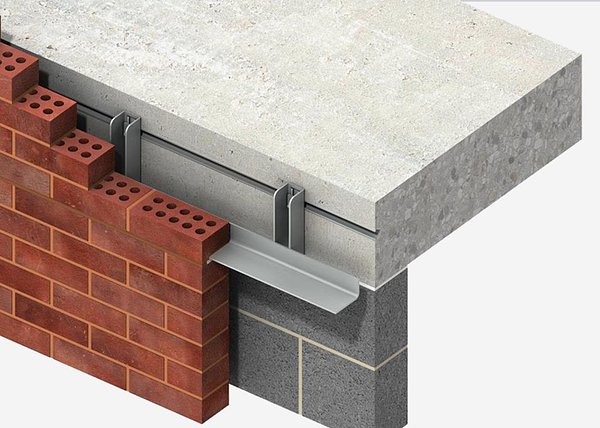

Masonry cladding on steel or concrete framed structures is normally supported by stainless steel shelf angle.

Helifix Masonry Repair Solutions

Helifix repair and reinforcement products, with their concealed non-disruptive installation techniques, help to preserve our built environment and strengthen existing masonry structures. The range comprises innovative helical wall ties, fixings and masonry repair systems.

Latest News

Holiday Closing 2026

Our offices will close from Thursday, 25th December 2025 and re-open at our usual business hours on Monday, 5th January 2026.

New Halfen Powerclick 100

The Halfen Powerclick System is a proven innovative technology for pipe supports in large-scale industrial plant construction. We are delighted to announce the addition of Halfen Powerclick 100 to our range, which provides superior on-site solutions for heavy-duty applications that are even more secure and sustainable for customers.