HALFEN Modular Pipe Support Systems

HALFEN POWERCLICK Modular Pipe Support Systems

Available in Australia exclusively from Leviat, HALFEN POWERCLICK is a pre-assembled, durable, safe and highly adaptable modular pipe support solution for various loads and piping applications.

The HALFEN POWERCLICK range includes a wide range of modular pipe support systems, pipe clamp & shoe accessories in different finishes. All POWERCLICK framing channels and bolts are toothed and form an interlocking connection. Clamshell design connectors provide excellent load transfer, in both shear and moment.

Developed for the chemical industry nearly 20 years ago, HALFEN POWERCLICK offers an innovative, time and cost saving alternative to traditional pipe supports made from secondary steel.Halfen Powerclick Systems 63 and 100 are available in hot-dip galvanized steel (FV), the compatible Halfen HZL 41/41 and Halfen HZL 41/22 mounting channels are available in hot-dip galvanized steel (FV) and also in stainless steel (A4). The zinc coating layer of > 50µm provides a nominal service life of 25 years, assuming an annual zinc loss of 2 µm (corrosivity category C4).

Key Features and Benefits

- Only four pre-assembled core POWERCLICK components

- Four channel sizes (41 & 22, 63 and the new 100) – fully interchangeable

- One pre-assembled bolt for all inter-connections

- Lightweight with a high torsional rigidity

- Modular and adjustable

- No welding on site

- Lower material stock levels

- Time and cost saving

- Load calculations according to EC3 and EN 13480-3

- 3D design software tools available to simplify the planning process: Aveva PDMS & E3D, Intergraph Smart3D, various 3D parts and assemblies libraries

Pipe enclosing components like pipe shoes and clamps are available from the POWERCLICK accessory range and a comprehensive range of cantiliver arms completes the POWERCLICK range.

System Components

Only four core lightweight components from the POWERCLICK 63 system can form a multitude of supports, Goalposts, L or T shapes, etc, and they can all be handled manually, without the need for special tools or lifting equipment.

POWERCLICK Base Plate

One base plate in three sizes fits any standard beam flange width from 75–300mm. The base plate opening fully encloses the channel and is attached to the steel structure using a universal beam clamp. The base plate can also be attached to concrete using a post drilled anchor from the HALFEN range. The channel slot can be positioned to face in any direction, by simply changing the location of the bolts in the base plate.

POWERCLICK Framing Channel

The toothed, slotted framing channels are available in 3 and 6 m standard lengths. A 41/22 channel is laser-welded into the 63/63 section. This closed profile resists a moment of torsional inertia equal to a steel HEB 160 beam, with much less weight.

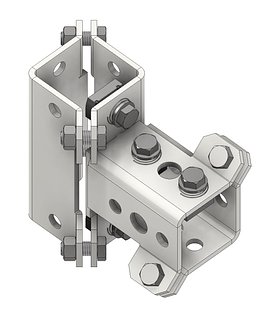

POWERCLICK Elbow Connector

Only 2 types of elbow connector are required to make nearly any type of support shape in the POWERCLICK 63 system. The elbow connectors fully enclose the connecting framing channels. By changing the positioning bolts of the elbow connector, the channel slot can be easily made to face in the required direction. Teeth in the channel and on the POWERCLICK bolts provide a slip-resistant mechancial connection.

POWERCLICK Beam Clamp

The universal POWERCLICK beam clamp adjusts to fit any beam with a flange thickness of 5-40mm. The four hardened teeth bite into the flange without affecting the corrosion protection, providing positive load transfer.

Latest News

Holiday Closing 2026

Our offices will close from Thursday, 25th December 2025 and re-open at our usual business hours on Monday, 5th January 2026.

New Halfen Powerclick 100

The Halfen Powerclick System is a proven innovative technology for pipe supports in large-scale industrial plant construction. We are delighted to announce the addition of Halfen Powerclick 100 to our range, which provides superior on-site solutions for heavy-duty applications that are even more secure and sustainable for customers.